There is a beast among us. It is ever present and lurks within the shadows of our business. All of us who are in the Franchised New vehicle retail business are well aware of its’ presence. It rears its’ ugly head from time to time and we all have to deal with the consequences it brings down upon us. It infects our mind, body and spirit. It feeds on vehicle inventory management decisions that were made without scientific facts. It eats our cash. It has its’ way with man-agers and Dealerships who still order vehicles by “gut feel” and factory rec-ommendations. It wreaks havoc to one of our most coveted items, our bottom line. It is the Floor Plan Monster.

I have been engaging in battle with this worthy adversary for over 30 years and have come to learn many things. It is cunning. It is self replicating. It

is demoralizing. Just when you think you have it under control, it rebounds stronger than Shaquille Oneal and knocks you down again and again. But the most important thing that I have learned is, it can be tamed, harnessed and even become one of your revenue producing allies. Its’ weakness is infor-mation. Information however, without implementation will not defeat it. Its’ Achilles heel is a new vehicle inventory management system that is implement-ed and used every day on every new vehicle inventory management decision that we make, both buying and selling.

Can you imagine what life would be like if your parts manager was stocking your shelves by “gut feel” or what the manufacturer wants them to stock?

It would be total chaos. He/she uses a stocking guide everyday. It is the absolute bible for the department. The average cost per part you stock is less than $40.00 and your store manages over 8,000 part numbers with preci-sion. Do your new vehicle department managers use an objective, data driven, easy to use, stocking guide on a daily basis? Have you ever heard them say, “I know what sells”? Are you running on floor plan credits month after month? The average cost per new vehicle now exceeds $25,000.00. Are you managing your New vehicle department inven-tory with precision?

Over the past 12 years I have liter-ally been in hundreds of New Vehicle Dealerships across the country. I have sat through many “wholesale / consen-sus / inventory allocation” meetings and most all of them were basically the same. The dealer would ask the members of the management team two basic questions. “How many did we sell in the previous period” and “how many do you think we are going to sell in the coming period”. Once those two numbers were determined, the decision was made as to how many they were going to purchase and com-mit to for that particular period. This is not an effective new vehicle inventory management system. This type of decision making process simply “feeds the Monster”.

It was once thought not long ago, that “knowledge was power”. That changed in the 90’s to the belief that “infor-mation was power”. We now know that true power is earned by coupling knowledge and information through “implementation”. Knowing what needs to be done and doing it are two very different things. The entire thrust of this article is to expose you to the ways in which hundreds of new vehicle dealerships across the country are working on keeping the majority of the floor plan credits in the house and are operating on a floor plan credit balance YTD.

Virtually all of the manufacturers today have the ability to make a vehicle appear on your lot between 4 and 6 weeks from the time you order. (some even much quicker) Sure there are a few exceptions, material holds, con-straints, etc, but by and large, normal system fill is less than 45 days. De-pending on the Manufacturer, those that have a floor plan assistance pro-gram will generally allow you enough floor plan credit to carry up to 71 days supply before incurring “net floor plan charges”. The secret then is to imple-ment a system that will allow you to carry more of the right inventory more of the time and not exceed a 71 days supply on the ground. Ideally, we shoot for a 60 day supply of ground stock and no more than a 60 day supply in the supply chain system. Sound like a pipe dream? It is not. It can, and does happen, but not without diligent daily implementa-tion of a new vehicle inventory management system.

The principle idea of any good vehicle inventory management system is to quickly give infor-mation to management that will lead to implementation and help accomplish the following:

- To continually phase in what we need and phase out what we do not.

- Make it easy to read, use and understand.

- Recommend some specific ac-tion that needs to be taken.

- Make decisions based on actual data, not “gut feel”.

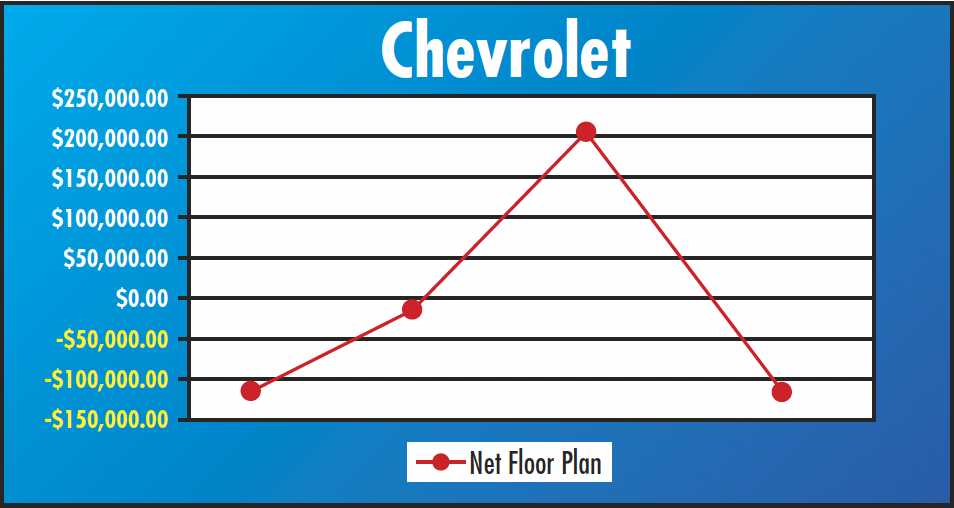

Pictured below is a picture of an actual dealership comparing the previous 4 years calendar YTD in net floor plan charges. As you can see there was over a $300,000.00 net swing from the end of 2005 to the end of 2006. This store averaged a little over 120 New vehicle sales per month for both 2005 and 2006. The difference? Days supply!!. This store decided to implement inventory management into their daily process and sold roughly the same number of units as the prior year. The days supply of inven-tory for 2005 averaged 105. Days supply for 2006 was reduced to and maintained at 63. Their gross went up per unit by over $100.00 simply because their quickness of turn increased. The $300,000.00 net floor plan swing all fell di-rectly to their bottom line. They tamed the floor plan monster. You can too.

Most used car managers are also largely resistant to inventory management systems. I have heard all the excuses. “I can’t control what comes in on trade”, “Yes, I know I need some of those, just dial 1-800 used cars and order me some” and “No computer can manage my inventory better than me,” are just a few. Perhaps it is because they generally fear accountability. I really don’t understand the resistance to something that will increase their personal W-2s. Let’s face it, this is a sizeable investment portfolio.

Invest In The Process

This department can often determine whether we make a net profit or not. The bottom line is that most dealerships need an inventory management system. There are many good ones out there. Most are less expensive than what you are paying for your parts inventory management system. Do yourself a favor – commit to making a change in your used vehicle department and in stall an inventory management system. Demand that the process is inviolable. Monitor its use and progress at least once a week. You will be glad you did. When it is running properly, and decisions are being made by the numbers, not by emotions, you will be turning your used vehicle inventory between 9 and 12 times a year. The numbers you can achieve will amaze you. It is not likely that you will begin achieving different results without changing current behavior.