We hove all heard some version of the story about the man who went to the doctor because he hod a pain in his shoulder. After woiting patiently, he was finally called by the nurse and escorted into the exominotion room. After waiting o period of time, the doctor finolly come into the room. After exchonging pleosontries, the doctor asked the man, uwhot seems to be the problem?” The potient explained to the doctor that every time he lifted his right orm obove his head it caused him o great deal of pain. The doctor responded by saying, “If every time you lift your right arm above your head it hurts, just stop doing that.”

This is a very trite analogy, but the point I om trying to make here is that those of us who have been in this business for any length of time have experienced who! I will refer to as “wholesale poin.” It comes in varying degrees ond it is never pleasant. Sometimes it hurts more than others, but each one of us hos experienced it. We never ask for it on purpose and we all would like to know how to get rid of it and not let it recur. It is not just a matter of “stop doing that” ond the pain will go away. Or is it? Maybe, Kenny Rogers put it best in his song “The Gambler,” when he sang, “You got to know when to hold’em and know when to fold’em.”

If there wos a “magic pill” or prescription that would eliminate wholesale pain, would you toke it? Unfortunately, there is no such thing os a magic pill, but there are many choices for curing this particular malady. By far, the most effective long-term remedy is to implement a comprehensive, doily inventory management system. The system must show us where we ore long, where we ore short and be very easy to use and understand. Every one of these “key” words is on active ingredient in formulating the prescription, ond it will not work without all of these ingredients combined: IMPLEMENT, COMPREHENSIVE, DAILY, INVENTORY, MANAGEMENT, SYSTEM. These “key” words ore defined as follows:

- IMPLEMENT: To carry out or to fulfill; to put something into effect or action

- COMPREHENSM: Including all; including everything so os to be complete; covering many things or a wide area

- DAILY: Done or occurring every doy

- INVENTORY: A record of a business’s current ossets (In this case, used vehicles)

- MANAGEMENT: The act of handling or controlling something, preferably successfully

- SYSTEM: A method or set of procedures for achieving something desired

Eliminating “wholesale pain” is simply choosing not to participate in vehicle segments that do not belong on your lot and having a system in place to identify these vehicles from day one. If it is wrong for your lot on doy one, it is even worse on doy 6 1 . This sounds easy. The truth is that with a wellthought-out system, you con determine which ones are “right” and which ones are “wrong” far your store an the doy of acquisition. If you know something is going to hurt, you are not likely to do it to yourself. The opposite is also true; if it is likely lo “feel good” you probably would want to do it, and maybe more of it.

You must first come to the reolizotion tho! your store cannot be all things to all people. Many factors ploy into determining why your customers are coming to your lot and who! they are looking for. These factors include demographics, new vehicle franchises represented, reputation, lot size, location, advertising budget, sales people, inventory choices and many more. Some vehicle categories, model years ond specific models simply cause you wholesale pain. When you determine who! those specific categories and vehicles ore, you con simply eliminate those vehicles from your inventory.

You should implement o system that will separate your soles, gross and inventory first by categories of vehicles (small cars, mid-size cars, sporty cars, fullsize cars, small pickup, full-size pickup, small sport utility, large sport utility, mini von and regular van) and then by the eight most recent model years within eoch category. Your stocking guide must also include your target supply number for eoch category and model year including the number of units and the desired ready to go ACV. I suggest your forget be no more than o 45- doy supply. Most large used vehicle operations ore now shoaling for o 35-doy supply.

You should implement o system that will separate your soles, gross and inventory first by categories of vehicles (small cars, mid-size cars, sporty cars, fullsize cars, small pickup, full-size pickup, small sport utility, large sport utility, mini von and regular van) and then by the eight most recent model years within eoch category. Your stocking guide must also include your target supply number for eoch category and model year including the number of units and the desired ready to go ACV. I suggest your forget be no more than o 45- doy supply. Most large used vehicle operations ore now shoaling for o 35-doy supply.

Your stocking guide needs to be based on actual sales rates, not forecasts. This “ideal” stocking guide number should then be compared on a daily basis to the actual availability for each category and model year. If you are long or short in any category, develop an action plan with your managers to correct the condition. Daily vigilance in seeing that the action plan is being implemented is vital. Remember, this is not guesswork or behavior based solely on opinions.

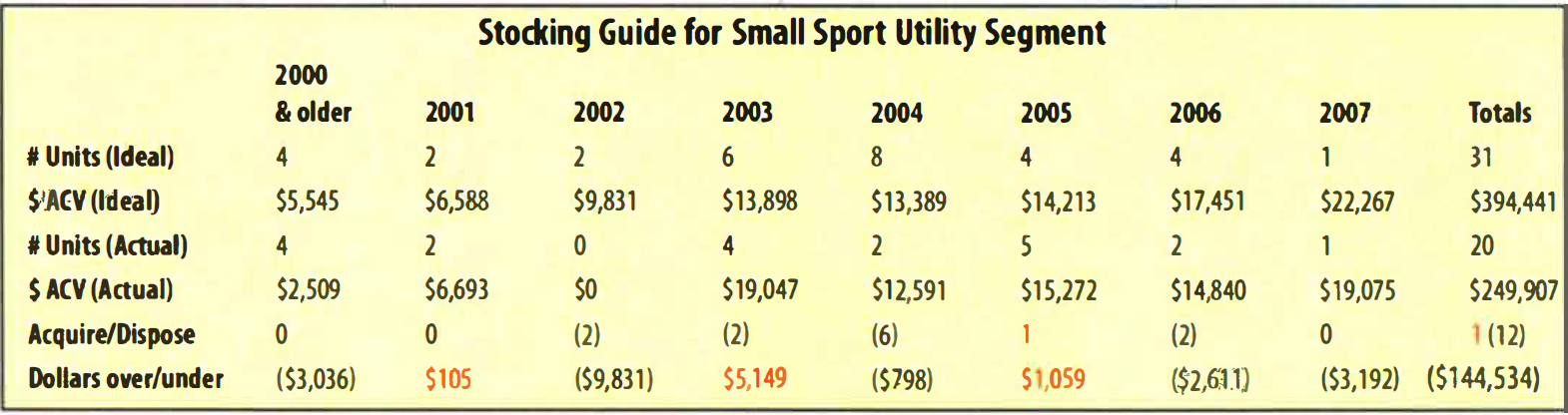

Pictured below is on example of a very effective stocking guide for the small sport utility segment of o dealership.

The first two rows ore what o 45- doy supply of units needs to be with the corresponding front-line ready overage ACV. These ideal stocking guide unit count numbers ore based upon the stores’ actual retail soles histories ond the ACV is the overage cost of those soles. The next two rows show the actual number of units in inventory and corresponding ACV. The last two rows simply show us what action is required as it relates to the number of units and how much money we ore over or under the stacking guide in real money.

We use this guide as o shopping list, on appraisal guide and inventory decision maker. As a shopping list, the above example clearly points out that we need 2004 small sport utilities with ready-lo-go money around the $14,000 area. As the appraiser and decision maker, if the next trade you ore evoluoting happens to be a 2005 BMW XS that is worth around 22,000, we know we wont to trade for the vehicle if possible, but it doesn’t fit our stocking guide. So, the appropriate action would be to secure a buy figure on it, try it for 10 days ond when/if it is still here in 10 days, cash it. Do not risk experiencing wholesale pain on something that simply doesn’t fit.

Over the years, many managers hove said they ore “too busy• to use, or even look ot, such o system. They “don’t wont to get bogged down in details.” They know what sells and what doesn’t. In reality, many managers fear accountability and they wont to keep the

“secrets” to inventory management to themselves os some sort of perceived job security. If that is the case in your store, make o change either in the manager, the current process or the manager’s thinking. You should invest in an inventory management system, that willbe implemented and used by all of your people all of the time. The benefits of this type of investment will for outweigh the cost. In closing, remember this: It is not very likely that you will begin achieving different results without changing current behavior.

One of the mast revealing facts that I have come across recently, as it relates to acquiring the correct inventory, comes from the Car Max annual report.

Did you know that over 50 percent of the vehicles Car Max acquired came from “off the street” purchases directly from customers? Are you actively identifying areas of soles opportunities and acquiring inventory lo fill these oreos? If not, you ore missing o tremendous gross opportunity and exacerbating the process of creating your own wholesale pain.

If you would like to see what o stocking guide for your store would look like, please e-mail

me a request for the stacking guide file. It is o simple-ta-use Excel file that you can populate with your existing inventory and begin the journey on the road to recovery from wholesale pain.